The Role of Membrane Switch Technology in Improving Product Interfaces

The Role of Membrane Switch Technology in Improving Product Interfaces

Blog Article

The Advantages of Using Membrane Changes in Customer Electronics

Membrane layer buttons are progressively acknowledged for their substantial advantages in customer electronic devices, specifically in boosting user interaction and enhancing manufacturing procedures. The adaptability in layout allows for tailored options that meet diverse consumer requirements.

Boosted Individual Experience

In today's affordable landscape of consumer electronic devices, improved individual experience is vital; nearly 85% of customers focus on user-friendly user interfaces. Membrane layer switches over play a vital duty in achieving this degree of usability. Their flat, inconspicuous style enables seamless integration into various devices, minimizing bulk while maintaining performance. This design aesthetic not only improves the visual appeal however additionally adds to an extra structured customer communication.

The tactile comments supplied by membrane switches is essential for leading individual activities, guaranteeing that commands are registered accurately. This responses mechanism decreases mistakes and heightens customer satisfaction, fostering a favorable partnership between the customer and the tool. The adjustable nature of membrane layer changes permits suppliers to customize user interfaces to particular individual requirements, making gadgets more obtainable and welcoming.

Additionally, membrane layer buttons can include backlighting and visuals overlays, even more boosting visibility and use in varied atmospheres. This adaptability ensures that tools stay practical and straightforward, no matter the setup. Overall, the integration of membrane layer changes into customer electronic devices considerably improves user experience, driving brand loyalty and contentment in an increasingly open market.

Cost-efficient Production

Customer electronics manufacturers are constantly seeking ways to stabilize top quality with cost, and membrane switches offer an engaging remedy for cost-effective production. membrane switch. These parts are inherently less complex than traditional mechanical switches, which lowers both production costs and intricacy. The light-weight layout of membrane switches enables lower shipping costs and easier assimilation into portable devices, additionally boosting their charm in an open market

Makers can generate membrane layer switches in high volumes, making the most of economic situations of scale. This mass manufacturing capacity makes sure constant top quality while dramatically decreasing per-unit expenses. Furthermore, the products made use of in membrane layer switches, such as polyester and polycarbonate, are typically cheaper than those required for standard button modern technologies, adding to total cost savings.

The manufacturing process for membrane changes normally needs less actions and less labor contrasted to other button kinds. This structured strategy not just conserves on labor costs however additionally speeds up time-to-market, allowing firms to respond promptly to customer demand. The mix of lowered product expenditures and efficient manufacturing processes placements membrane switches over as a clever financial investment for producers aiming to provide top notch customer electronic devices at competitive rate factors.

Design Versatility and Modification

While standard mechanical buttons often impose constraints on design as a result of their mass and needed installing mechanisms, membrane buttons give unrivaled adaptability and personalization alternatives for customer electronics. This ingenious technology enables designers to develop sleek, low-profile user interfaces that can perfectly incorporate right into various product aesthetics, from mobile phones to kitchen appliances.

Membrane layer switches can be created in virtually any kind of form or size, enabling manufacturers to customize the design to details ergonomic and useful needs. This flexibility not only click over here now improves user experience yet also enables visit this site imaginative designs that align with brand name identification. Moreover, the usage of published graphics on membrane layer changes provides the chance for vivid colors and elaborate layouts, which can be quickly modified without substantial cost effects.

Additionally, membrane layer switches can include numerous functionalities into a single layer, lowering the demand for several components and simplifying setting up processes. This structured design technique decreases space and weight, making it perfect for small consumer electronics. Overall, the style flexibility and personalization abilities of membrane switches over encourage producers to innovate, inevitably bring about even more user-friendly and appealing products.

Durability and Integrity

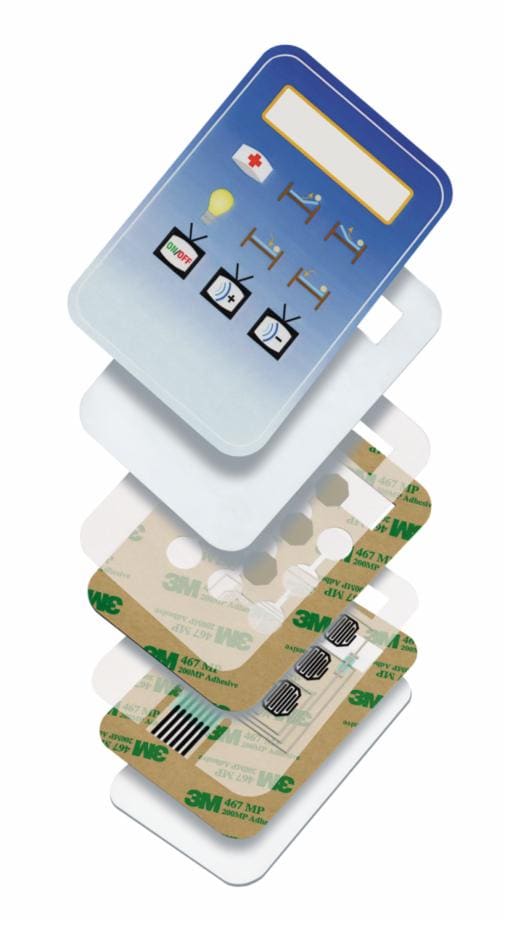

As technology proceeds to evolve, the durability and dependability of membrane switches have ended up being important factors to consider for manufacturers in the consumer electronics industry. Membrane layer switches are designed to stand up to rough ecological problems, consisting of temperature fluctuations, moisture, and dirt exposure. Their durable construction usually entails multi-layered products that offer a reliable barrier against impurities, guaranteeing longevity and consistent efficiency.

Along with environmental resistance, membrane switches over offer superior mechanical reliability. Unlike standard mechanical switches, which may wear with time, membrane changes make use of a covered layout that minimizes the danger of mechanical failure. The lack of relocating parts not only improves their life expectancy yet also minimizes deterioration, making them ideal for high-usage applications.

Furthermore, membrane layer buttons can sustain a significant variety of actuations without loss of performance, frequently surpassing countless cycles (membrane switch). This resilience equates to reduce replacement costs and decreased downtime for customers and manufacturers alike. In general, the combination of ecological durability and mechanical reliability makes membrane layer changes a tactical choice for consumer electronic devices, guaranteeing that tools continue to be reliable and functional throughout their desired life-span

Streamlined Item Growth

The durability and integrity of membrane layer switches dramatically add to streamlined item growth in the consumer electronic devices industry. By incorporating these buttons early in the style process, suppliers can lower the complexity and number of parts called for in their visit site items. Membrane buttons are lightweight and small, permitting for extra efficient area application within tools, which can result in streamlined assembly processes.

The ease of manufacturing membrane buttons also plays an essential function in product development. With modern printing methods and products, production can be scaled effectively, decreasing preparations and decreasing waste. This results in lower manufacturing prices, boosting overall productivity.

Verdict

In conclusion, membrane changes substantially boost customer electronics by offering an improved individual experience, cost-effective manufacturing procedures, and versatile layout choices. The integration of membrane layer changes represents a tactical option for producers looking for to optimize product style and performance.

Membrane buttons are progressively acknowledged for their substantial benefits in customer electronic devices, especially in improving individual communication and streamlining production processes. Additionally, the products used in membrane switches, such as polyester and polycarbonate, are often less costly than those needed for traditional button innovations, adding to general expense savings.

The production process for membrane layer switches over usually calls for less steps and less labor compared to other button kinds. Unlike standard mechanical buttons, which may wear out over time, membrane changes make use of a covered style that minimizes the risk of mechanical failure.In conclusion, membrane switches over considerably enhance consumer electronics by giving an enhanced individual experience, economical production procedures, and flexible layout alternatives.

Report this page